|

Kronos Precision Extrusion Co.Ltd

|

65mm PA66GF25 Hollow Chamber Thermal Break Polyamide Insulating Profiles

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

Polyamide Struts - Multi Cavity Thermal Insulation Polyamide Strips

Material: PA66 GF25

Processing: Extrusion

Width: 65mm

Feature: Hollow Chamber

Aluminum is a highly thermal conductive material that will rapidly transfer exterior climatic temperature unless something is done to stop the thermal conduction. A Thermal Break (also known as Insulating Profile, Thermal Barrier Strut, Insulating Bar) is a poor conductor of heat. It separates the outer and inner aluminum frames thermally from each other. This plastic thermal barrier profile acts as a barrier to prevent direct heat transfer through highly heat conductive aluminum profile.

A POLYAMIDE thermal break system will improve thermal performance while maintaining the structural and long-term durability of the fenestration unit. Aluminum is 533 times more conductive than polyamide insulating strips. Thermal Strut involves two separate extrusions and joins them through the use of engineered structural polymide strut. Both the inside and outside aluminum profiles are extruded independently with a cavity that will ultimately receive the strut.

Kronos Precision Extrusion is the leading manufacturer and supplier of high-end Glass Reinforced Polyamide Insulating Profiles for many of most energy-efficient aluminum window, door, and curtain wall products with growing presence in international markets.

Kronos's thermal strut is made of fiberglass reinforced virgin polyamide with glass fibers oriented in 3 directions for optimal structural performance. Strut offers increased energy savings with varying thermal separation widths including those greater than any other thermal break system. Structural performance and mechanical response are exceptional with the multidirectional glass fibers oriented in 3D to give improved load transfer.

Each polyamide strip is designed and manufactured in-house in our facilities to ensure control over the schedule, quality and cost requirements and thus allowing us to consistently deliver top quality products to our customers economically and on time.

Extremely Smooth Surfaces, Tighest Tolerance, Outstanding High Precision, all of these set Kronos apart from other thermoplastics extruders. Our polyamide profiles yield best-in-class thermal performance and exceeds not only current codes, but also exceeds every country's stringent green building codes and standards in the market today.

The technical know-how accumulated over dacades of experience in supplying PA66 insulating strips to the leading manufacturers of aluminum windows, doors, facades, and curtain wall systems in China and worldwide, enables KRONOS to technically team up with the clients in the development of new highly performing systems, or improving the insulating properties of the existing ones.

Kronos thrives upon Wide and Complex polyamide extrusions that challenge today's extrusion capabilities. We pride ourselves in taking on the thermoplastics extrusions that others say Can't Be Done or Too Difficult.

Aiming always for the best quality, energy efficient aluminium windows, doors, facades, and curtain wall systems using Kronos's polyamide insulating profiles are the absolute first choice for new constructions and renovation projects in which compromise is not an option.

Technical Specifications:

Product Name: Thermal Insulation Polyamide Profiles, Polyamide Thermal Break Strips, Thermal Barrier, Polyamide Insulating Profiles

Manufacturer: Kronos Precision Extrusion

Kronos Model No.: 650H01

Material: Virgin Polyamide 66 + 25% Pure Glass Fiber (PA66 GF25)

Processing: High Precision Polyamide Extrusion

Polyamide Width: 65mm

Standard Length: 6 meters/piece or customized

Profile Density: 1.30 ± 0.05 g/cm³

Shore Hardness: 80

Polyamide Strips Color: Black

Features: Hollow Chamber, Multi Cavity, High Precision, Extremely Smooth Surfaces, Tight Tolerance

Standards Carried: European Standard EN 14024:2004 and Chinese GB/T 23615.1-2017

Applications: Thermally Broken Aluminum Doors and Windows, Passive House etc.

65mm Hollow Chambered Polyamide Thermal Break Profiles (PA66 GF25%) produced by Kronos Precision Extrusion

The wider the polyamide thermal break strips, the better insulation.

Photos of Kronos's 65mm Hollow Chambered (Shape H) Polyamide Thermal Break Profiles

Kronos adopts 20 degree standardized groove for the polyamide insulating profiles.

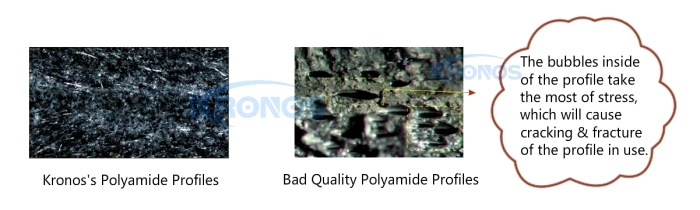

Kronos's Polyamide Thermal Barrier Strips in Comparison with Bad Quality Polyamide Insulating Profiles

Thermal Insulation Polyamide Profiles of different widths and geometries produced by Kronos Precision Extrusion

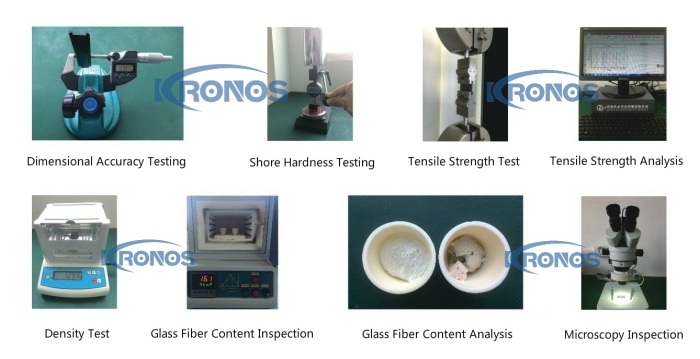

All batches of Kronos's polyamide profiles are subject to a rigorous inspection process prior to delivery.

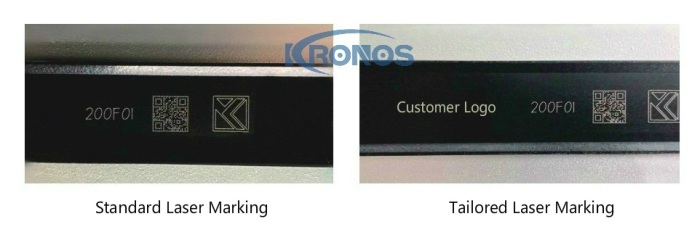

Kronos provides standard and custom Laser Marking for easier traceability and improved quality control, adding extra value to your products and company.

Glass Fiber Reinforced PA66 GF25 Thermal Break Polyamide Strips ready for delivery

Standard PA66GF25 Polyamide Thermal Break Strips in stock

Offering nothing but the best, we pride ourselves with the use of state-of-the-art machinery to produce the top-notch quality thermal insulating polyamide strips. They are built with careful attention to detail and superb craftsmanship using innovative engineering with the leading technologies.

Our friendly and professional team is committed to ensuring you're happy not only with the product you choose, but also the service you receive from everyone at Kronos Precision Extrusion. We listen to what our customers request of us, addressing these needs, always aiming to surpass your expectations.

As you learn more about Kronos, you will discover that we are trying to achieve the same thing as you – PERFECTION.

Exchange of Know-How-The Milux Windows and the Kronos Precision Extrusion Team

Whatever your thermoplastics extrusion challenges are, the professional specialists of Kronos Precision Extrusion are always here for YOU with the Optimum solutions.