|

Kronos Precision Extrusion Co.Ltd

|

18mm Thermal Strut Polyamide Insulating Profiles for Aluminum Windows and Doors

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Thermal Struts Polyamide Insulating Strips

Material: Virgin PA66 GF25

Process: Precision Polyamide Extrusion

Width:18mm

App: Alu Windows and Doors

Overview

The aluminum windows and doors of today are a lot better than the older styles of the 1970s and 1980s. One of the biggest advantages of aluminum is that it's very light but still strong. It's durable and doesn't require much maintenance, especially with a factory-baked or anodized finish. If you have windows with unusual shapes, you might consider aluminum because it can easily be manipulated into the shape you need.

Compared to wood and vinyl windows, aluminum windows are exceptionally strong and durable. That is not to say that wood and vinyl windows are not durable, but the weight to strength ratio of aluminum windows allows them to have the largest selection of window configurations. In fact, they can be as much as three times the strength of vinyl windows and more than 50 times as strong as wood windows-making them perfect for both residential and commercial applications.

However, aluminum doesn't hold heat in well. The thermal conductance of aluminum is high. Thus aluminum windows and doors may not work well in cold climates. Condensation or even frost forms inside the windows/doors and can present a variety of problems which bother tens of millions of households constantly. These are where Kronos's Thermal Struts-Polyamide Insulating Profiles come into play.

Kronos Precision Extrusion is an innovative Singapore-Germany joint venture that specializes in developing and manufacturing Thermal Insulating Polyamide Profiles with Cutting-Edge High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded profiles from Virgin Polyamide 66 (PA66 or Nylon 66) and other materials for aluminum windows, doors, facades, curtain walls, operating rods, solar panels, automotive sunroof blind rails, and various engineering applications.

Unlike aluminum, polyamide is non-conductive material and the Polyamide Profiles work as a separator (Thermal Break, Thermal Barrier, or Thermal Strut) between the inner and outer aluminum frames to prevent the temperature transfer through the frame and condensation on the inside frame.

Adding insulating, thermal, polyamide strut to aluminum framing members separates the inside and outside metal, which greatly enhances a window, door, skylight, storefront, facade or curtainwall system's thermal performance. This thermal break reduces the amount of heat transfer, therefore saving energy and increasing occupant comfort dramatically.

On today's market, the best insulation strips are made of Polyamide 66 (PA66 or Nylon 66) with 25% Fiber Glass reinforcement. The use of polyamide 66 resins reinforced with 25% glass fiber in the production of polyamide insulation strips makes these components in combination with the aluminum profile, behave similar to the aluminum metal. Thermal struts of glass-reinforced nylon have very similar expansion coefficients to aluminum and will not separate over years of seasonal hot-cold cycles. Water and air will not have a chance to penetrate this superior thermal barrier.

Kronos is a Clear Winner in head-to-head competition. We pride ourselves with the use of state-of-the-art machinery and unique technical know-how to produce thermal insulation polyamide profiles. They are produced with careful attention to detail and superb craftsmanship using innovative engineering with the newest technologies. Extremely Smooth Surfaces, Awesome Low Tolerances, Mind-Blowing High Precision, these are the very right words to describe Kronos's polyamide strips.

Ensuring sustainability is at the heart of what we do. For over 20 years, Kronos's innovative, high-precision polyamide 66 based insulation profiles for aluminum doors, windows, and facade systems have helped improve quality and comfort, while delivering energy savings and reducing CO2 emissions worldwide.

When it comes to Thermal Insulation Polyamide Profiles and High Precision Plastic Extrusion, Kronos is truly Outstandingly Good. If you buy Thermal Break Polyamide Profiles from Kronos Precision Extrusion, you'll instantly know just how accurate they are and how precisely they fit together with your aluminum frames.

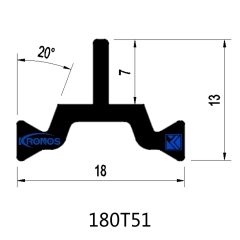

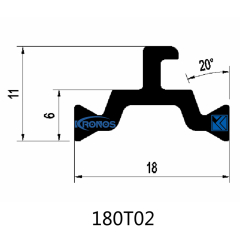

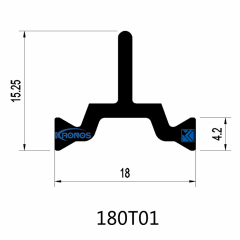

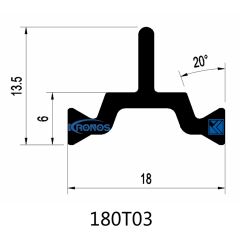

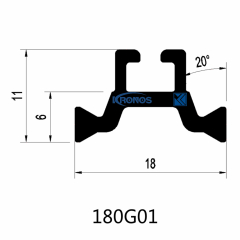

Technical Specifications:

Product Name: Thermal Insulation Polyamide Profiles, Thermal Break Polyamide Strips, Thermal Struts, Polyamide Struts, Thermal Barrier, Heat Insulating Polyamide Strips

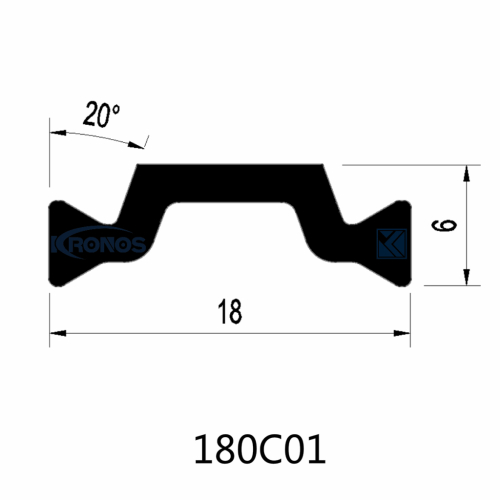

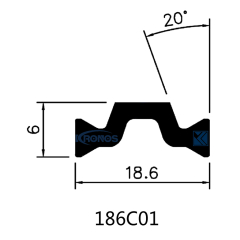

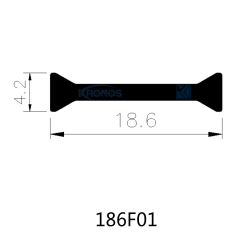

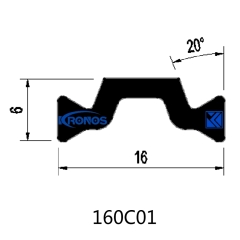

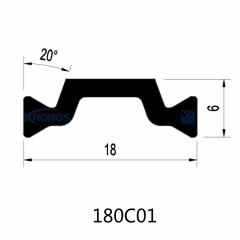

Kronos Model No.: 180C01

Material: Virgin Polyamide PA66 GF25

Processing: High Precision Polyamide Extrusion

Width: 18mm

Standard Length: 6 meters/piece

Density: 1.30 ± 0.05 g/cm³

Polyyamide Profile Color: Black

Standards: European Standard EN 14024:2004 & GB/T 23615.1-2017

Certification: IATF 16949:2016

Applications: Thermally Broken Aluminum Windows and Doors, Passive Windows, Energy Efficient Buildings, Passive House, Sustainable Buildings etc.

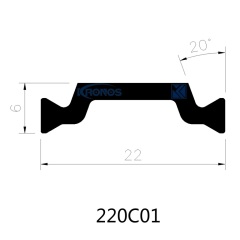

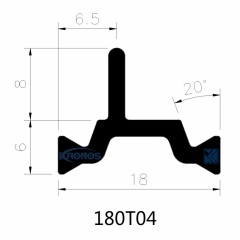

Thermal Strut-Polyamide Insulating Strip of 180C01 is shown as below

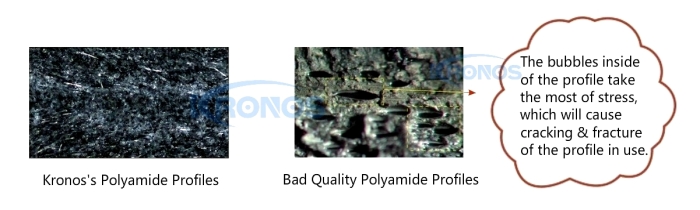

25% Pure Glass Fiber reinforcement guarantees the Thermal Struts (PA66 GF25) strength and excellent reliability.

When it comes to the Precision & Quality of the Thermal Insulating Polyamide Strips, Kronos Precision Extrusion is proudly confident.

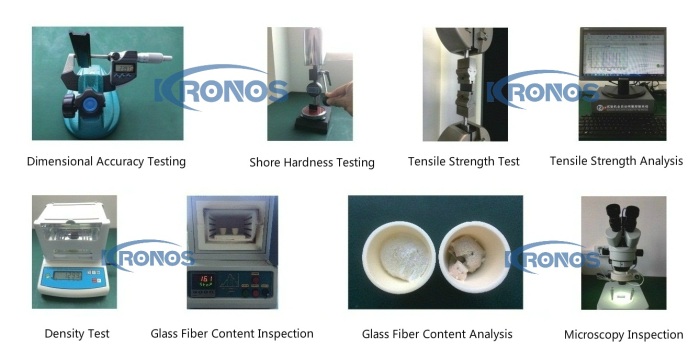

At Kronos Precision Extrusion, Thermal Break Polyamide Strips MUST go through Rigorous Quality Check prior to delivery.

Kronos Precision Extrusion uses Fumigation-Free wooden case packaging to ensure the thermal break polyamide strips well stored.

Aluminum Windows & Doors manufacturers are greatly impressed by the AWESOME Quality of Kronos's Polyamide Strips and it's Capabilities.